Iqela leTops libonelela ngeendlela ezahlukeneyo zoomatshini bokuzalisa umgubo we-semi-auto. Sinetafile zedesktop, iimodeli ezisemgangathweni, uyilo olukwinqanaba eliphezulu elineentsimbi ezibambekayo, kunye neentlobo zeengxowa ezinkulu. Sinomthamo omkhulu wemveliso kunye neteknoloji ye-auger powder filler. Sinelungelo elilodwa lomenzi wechiza kwinkangeleko yezizalisi ze-servo auger.

Iindidi ezahlukeneyo zeSemi-Auto Powder Filling Machine

Uhlobo lweDesktop

Lo ngowona mzekelo umncinci wetafile yelabhoratri. Yenzelwe ngokukodwa izinto ezimanzi okanye eziphantsi kwamanzi ezifana nomgubo wekofu, umgubo wengqolowa, i-condiments, iziselo eziqinileyo, amayeza ezilwanyana, i-dextrose, amayeza, i-powder additives, i-talcum powder, i-pesticides yezolimo, i-dyestuff, njalo njalo. Olu hlobo lomatshini wokuzalisa unako kokubili umthamo kunye nokugcwalisa umsebenzi.

| Umzekelo | TP-PF-A10 |

| Inkqubo yokulawula | I-PLC kunye nesikrini sokuchukumisa |

| Hopper | 11L |

| Ukupakisha Ubunzima | 1-50g |

| Ukunciphisa ubunzima | Nge-auger |

| Weight Feedback | Ngokulinganisa ngaphandle kweintanethi (kumfanekiso) |

| Ukupakisha Ukuchaneka | ≤ 100g, ≤±2% |

| Ukuzalisa isantya | 40 - 120 amaxesha ngomzuzu |

| Ukunikezwa Amandla | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.84 KW |

| Ubunzima obupheleleyo | 90kg |

| Imilinganiselo iyonke | 590×560×1070mm |

Uhlobo olusemgangathweni

Olu hlobo lokuzaliswa lufanelekile ukuzaliswa kwesantya esisezantsi. Ekubeni ifuna ukuba umqhubi abeke iibhotile kwipleyiti engaphantsi kwe-filler kwaye asuse ngokwasemzimbeni iibhotile emva kokuzaliswa. Iyakwazi ukuphatha zombini iibhotile kunye neepakethi zepokhi. I-hopper inokwenziwa ngokupheleleyo ngentsimbi engenasici. Ukongeza, inzwa inokuba yinzwa yefolokhwe okanye inzwa yefoto yombane.

| Umzekelo | TP-PF-A11 | TP-PF-A14 |

| Inkqubo yokulawula | I-PLC kunye nesikrini sokuchukumisa | I-PLC kunye nesikrini sokuchukumisa |

| Hopper | 25L | 50L |

| Ukupakisha Ubunzima | 1 - 500g | 10 - 5000g |

| Ukunciphisa ubunzima | Nge-auger | Nge-auger |

| Weight Feedback | Ngokulinganisa ngaphandle kweintanethi (kumfanekiso) | Ngokulinganisa ngaphandle kweintanethi (kumfanekiso) |

| Ukupakisha Ukuchaneka | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% |

| Ukuzalisa isantya | 40 - 120 amaxesha ngomzuzu | 40 - 120 amaxesha ngomzuzu |

| Ukunikezwa Amandla | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.93 KW | 1.4 KW |

| Ubunzima obupheleleyo | 160kg | 260kg |

| Imilinganiselo iyonke | 800×790×1900mm | 1140×970×2200mm |

Ngohlobo lweKlampu yesingxobo

Le semi-automatic filler ene-pouch clamp ilungele ukugcwaliswa kwesingxobo. Emva kokunyathela ipleyiti enyovwayo, i-pouch clamp iya kuyigcina ngokuzenzekelayo ibhegi. Iya kukhulula ngokuzenzekelayo isikhwama emva kokuzaliswa.

| Umzekelo | TP-PF-A11S | TP-PF-A14S |

| Inkqubo yokulawula | I-PLC kunye nesikrini sokuchukumisa | I-PLC kunye nesikrini sokuchukumisa |

| Hopper | 25L | 50L |

| Ukupakisha Ubunzima | 1 - 500g | 10 - 5000g |

| Ukunciphisa ubunzima | Ngeseli yomthwalo | Ngeseli yomthwalo |

| Weight Feedback | Impendulo yobunzima kwi-Intanethi | Impendulo yobunzima kwi-Intanethi |

| Ukupakisha Ukuchaneka | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% |

| Ukuzalisa isantya | 40 - 120 amaxesha ngomzuzu | 40 - 120 amaxesha ngomzuzu |

| Ukunikezwa Amandla | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 0.93 KW | 1.4 KW |

| Ubunzima obupheleleyo | 160kg | 260kg |

| Imilinganiselo iyonke | 800×790×1900mm | 1140×970×2200mm |

Uhlobo lwesingxobo esikhulu

Ngenxa yokuba imodeli enkulu kunazo zonke, i-TP-PF-B12 idibanisa iplate ephakamisa kwaye iyancipha isikhwama ngexesha lokuzalisa ukunciphisa uthuli kunye nephutha lobunzima. Ngenxa yokuba kukho iseli yomthwalo ebona ubunzima bexesha langempela, ubunzima buya kubangela ukuchaneka xa i-powder ichithwa ukusuka ekupheleni kokugcwalisa ukuya ngaphantsi kwesikhwama. I-plate iphakamisa isikhwama, ivumela ityhubhu yokuzalisa ukuba inamathele kuyo. Ngethuba lenkqubo yokuzalisa, iplate iwa ngobumnene.

| Umzekelo | TP-PF-B12 |

| Inkqubo yokulawula | I-PLC kunye nesikrini sokuchukumisa |

| Hopper | 100L |

| Ukupakisha Ubunzima | 1kg - 50kg |

| Ukunciphisa ubunzima | Ngeseli yomthwalo |

| Weight Feedback | Impendulo yobunzima kwi-Intanethi |

| Ukupakisha Ukuchaneka | 1 - 20kg, ≤± 0.1-0.2%, > 20kg, ≤± 0.05-0.1% |

| Ukuzalisa isantya | 2-25 amaxesha ngomzuzu |

| Ukunikezwa Amandla | 3P AC208-415V 50/60Hz |

| Amandla Aphelele | 3.2 KW |

| Ubunzima obupheleleyo | 500kg |

| Imilinganiselo iyonke | 1130×950×2800mm |

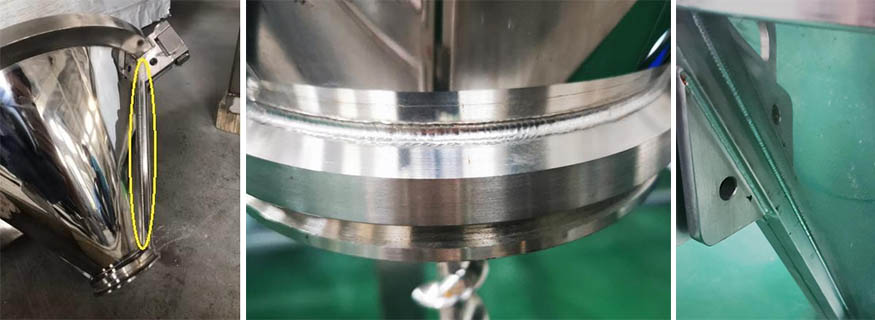

Amacandelo aneenkcukacha

IHopper enesiqingatha esivulekileyo

Le hopper yokwahlula kwinqanaba kulula ukuyivula kunye nokugcina.

Ihopper ejingayo

Ngenxa yokuba akukho ndawo kwindawo ephantsi

A.Optional Hopper

Uhlobo lwesikrufu

Akukho zithuba zokufihla umgubo ngaphakathi, kwaye kulula ukuyicoca.

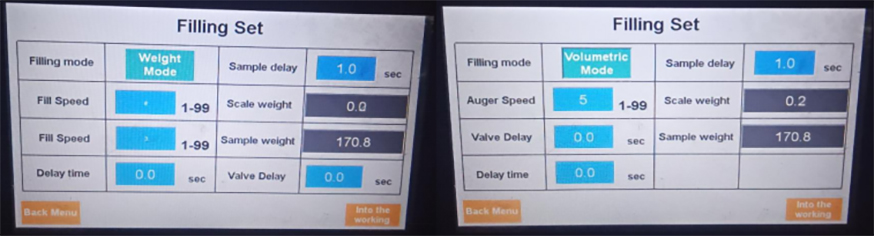

B.Imo yokuzalisa

Kufanelekile ukuzalisa iibhotile / iingxowa ezinobude obuhlukeneyo. Jika ivili lesandla ukuphakamisa kunye nokunciphisa isigcwalisi. Umphathi wethu ujiyile kwaye womelele kunabanye.

I-welding epheleleyo, kuquka i-hopper edge, kwaye kulula ukuyicoca

Kulula ukutshintsha phakathi kobunzima kunye neendlela zevolumu.

Imo yevolumu

Umthamo we powder uyancitshiswa ngokuguqula i-screw umjikelezo omnye usisigxina. Umlawuli uya kugqiba ukuba zingaphi izijikelezo ekufuneka zenziwe isikrufu ukuze sifumane ubunzima bokuzalisa obufunwayo.

Indlela yobunzima

Ngaphantsi kweplate yokuzalisa iseli yomthwalo elinganisa ubunzima bokuzalisa ngexesha langempela. Ukuzaliswa kokuqala kukhawuleza kwaye kuzaliswe ngobuninzi ukufezekisa i-80% yenjongo yokuzalisa ubunzima. Ukuzaliswa kwesibini kuncinci kwaye kuchanekileyo, ukongeza i-20% eseleyo ngokusekelwe kwisisindo sokuzalisa ngexesha.

Imowudi yobunzima ichanekile ngakumbi, kodwa icotha kancinane.

Isiseko semoto senziwe ngentsimbi engatyiwa 304.

Umatshini wonke, kubandakanya isiseko kunye nesibambi semoto, wakhiwe nge-SS304, eyomelele kwaye ikumgangatho ophezulu. Isibambi semoto asenziwanga nge-SS304.

C. Auger Ukulungisa Indlela

D.Ivili Lesandla

E. Inkqubo

F.Motor Base

G.Air Outlet

E. Ufikelelo lwemveliso ezimbini

Iibhotile ezinobunzima bokuzalisa obufanelekileyo zidlula kwindawo enye yokufikelela.

Iibhotile ezinobunzima bokuzaliswa obungafanelekanga ziya kunqatshelwa ngokuzenzekelayo ukufikelela kwibhanti echaseneyo.

F. Ubungakanani obahlukeneyo bokulinganisa i-auger kunye nemilomo yokuzalisa

Ingqikelelo yomatshini wokuzalisa ichaza ukuba ubungakanani bomgubo owenziwe phantsi ngokuguqula i-auger isangqa esinye silungisiwe. Ngenxa yoko, iisayizi ezininzi ze-auger zinokusetyenziswa kwiindidi ezahlukeneyo zokuzalisa ubunzima ukufezekisa ukuchaneka ngakumbi kunye nokugcina ixesha.

Isayizi nganye ye-auger inobungakanani obuhambelanayo netyhubhu ye-auger. Umzekelo, i-screw ye-38mm ifanele ukuzaliswa kwe-100g-250g.