Yintoni iumgca wokupakisha?

Masifunde ntoniumgca wokupakisha wemveliso yomgubokukuba, isebenza njani, zeziphi iimveliso ezimele ukusetyenziswa, kunye nokunye okuninzi.

A umgca wokupakisha wemveliso yomguboluluhlu oludityanisiweyo lwezixhobo kunye noomatshini abasetyenziselwa ukuguqula iimpahla zibe yifomu yazo yokugqibela epakishweyo kuyo yonke inkqubo yokupakisha. Ihlala ibandakanya i-assortment yoomatshini abazenzekelayo okanye abazenzekelayo abalawula iinkqubo ezahlukeneyo zokupakisha, kubandakanya ukuzaliswa, ukufaka i-capping, ukuleyibheli kunye nokutywinwa. Izinto ezahlukeneyo zomgubo zilungele imigca yokupakisha.

Umgca wokupakisha wemveliso yomguboimizi-mveliso: Iintambo zokupakisha ukutya neziselo, amayeza, izinto zokhathalelo lomntu, iimpahla zendlu, kunye namanye amashishini.

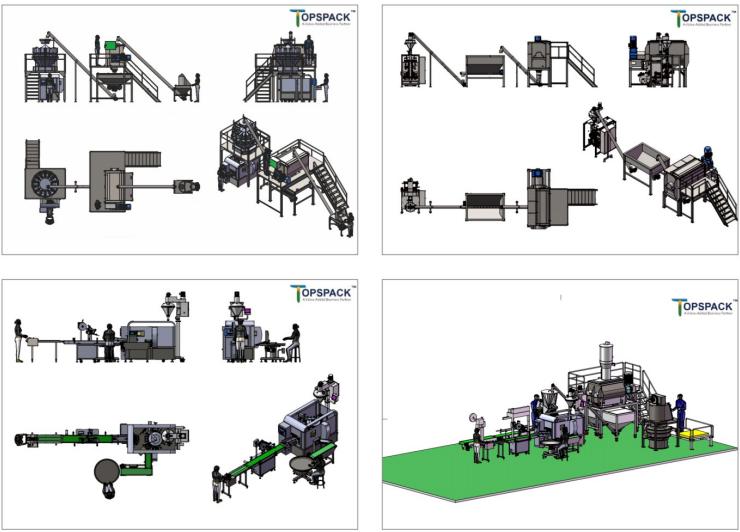

Seta u-A umgca wokupakisha wemveliso yomgubo.

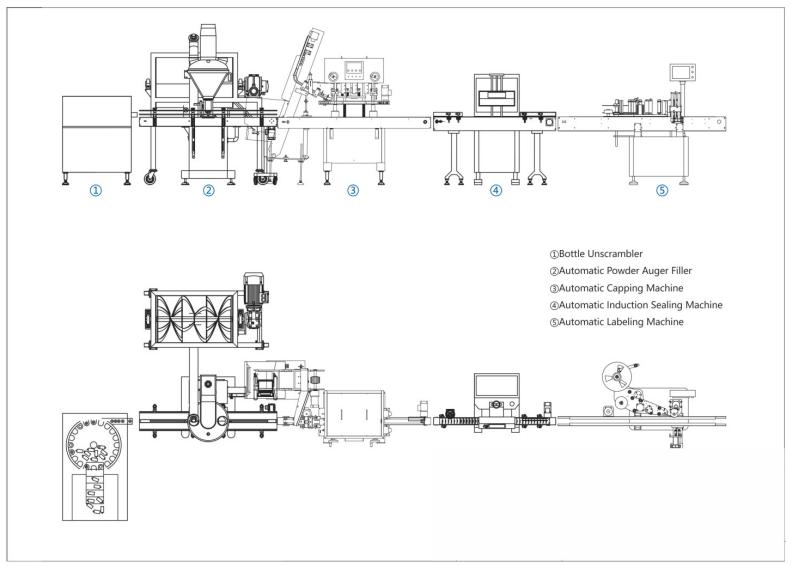

Ibhotile i-unscrambler + i-auger filler + umatshini wokuvala ozenzekelayo + umatshini wokutywina wefoyile

Seta B umgca wokupakisha wemveliso yomgubo

Ibhotile i-unscrambler + i-auger filler + umatshini wokuzifaka ozenzekelayo + umatshini wokutywina wefoyile + umatshini wokubhala

Sikwaneseti eyahlukileyo yokuxuba umgubo kunye nenkqubo yokupakisha:

Inokudityaniswa kunye ne-bottle unscrambler + i-automatic powder auger filling + umatshini we-capping ozenzekelayo + umatshini wokutywina ozenzekelayo wokutywina + umatshini wokuleyibhela ngokuzenzekelayo.

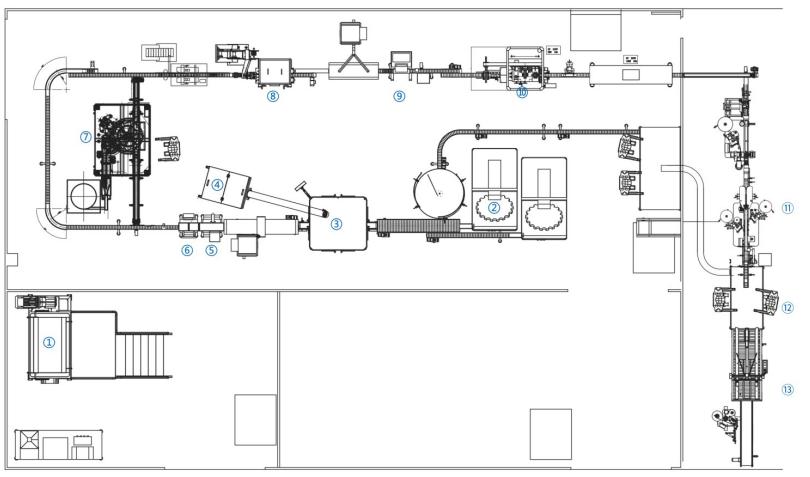

Inokuthi idityaniswe kunye nomatshini wokuxuba + ibhotile engabonakaliyo + i-dual head auger filler + screw conveyor + metal detector + ishekhi sobunzima + umatshini ozenzekelayo ojikelezayo we-capping machine + umatshini ozenzekelayo wokuvala umtshini + induction sealer + umkhono weleyibhile + multi-function labeler + itafile yokupakisha + umatshini wekhathuni.

Awona malungu aqhelekileyo aumgca wokupakishaziquka:

Umatshini wokuzalisa: Lo matshini wokuzalisa unokulinganisa, uzalise, kwaye wenze imisebenzi emininzi. Lo matshini ulungele ukupakisha zombini iipowders eziqukuqelayo, ezinje ngomgubo wobisi, kunye nezinto ezingafunekiyo zegranular ngenxa yokuyila kwayo, ulwakhiwo oluyilwe kakuhle. Njengoko isebenzisa i-auger filler ekhethekileyo kunye nokulandelela ixesha lokwenyani esekwe kwikhompyuter, ikwachaneke ngendlela emangalisayo kwaye isebenza kakuhle.

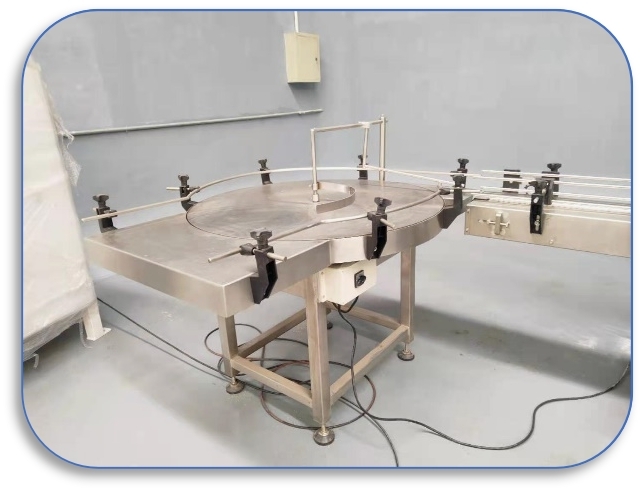

Abahambisi: Bathutha iimpahla ecaleni kwendlela yokupakisha. iqinisekisa ukuhamba ngokungenamthungo kwemathiriyeli koomatshini bokupakisha abaninzi. Kuxhomekeka kwinto efunekayo kwinkqubo yokupakisha, isenokuba ngabahambisi bebhanti, iirola zokuhambisa, okanye olunye uhlobo.

Umatshini wokuvala ibhotile: Umsebenzi womatshini wokuvala ibhotile kukujija iibhotile ngokuzenzekelayo. Oku kwenziwa ngokukodwa ukuba kusebenze kunye neenkqubo zokupakisha ezizenzekelayo. Lo matshini ngumatshini we-capping oqhubekayo, ngokuchasene neentlobo eziqhelekileyo eziqhelekileyo. Lo matshini usebenza bhetele xa ucinezela iziciko ngokukhuselekileyo kwaye ubangela ukubhoboza okuncinci kunokuvalwa kwe-intermittent capping.

Umatshini wokuLayibhila: Lo matshini kulula ukuwusebenzisa, uzimele, kwaye unexabiso elifanelekileyo. Ibonisa isikrini esichukumisayo esifundiseka ngokukhawuleza kwaye sicwangciseke. Kwi-microprocessor edibeneyo, iiparameters ezahlukeneyo zomsebenzi zirekhodwa ukwenzela ukuba kube lula kunye nokutshintsha ngokukhawuleza.

Ixesha lokuposa: Apr-03-2024