Ividiyo

Inkcazo ngokubanzi

I-TP-TGXG-200 i-Automatic Bottle Capping Machine isetyenziselwa ukujiya ii-caps kwiibhotile ngokuzenzekelayo. Isetyenziswa ngokubanzi ekutyeni, kumayeza, kumashishini ekhemikhali njalo njalo. Akukho mda kwimilo, izinto eziphathekayo, ubungakanani beebhotile eziqhelekileyo kunye ne-screw caps. Uhlobo oluqhubekayo lwe-capping lwenza i-TP-TGXG-200 ivumelane nesantya sokupakisha ezahlukeneyo. Lo matshini ngokwenene uneenjongo ezininzi, osetyenziswa ngokubanzi kwaye kulula ukusebenza. Xa kuthelekiswa nohlobo lwesiqhelo lokusebenza oluphakathi, i-TP-TGXG-200 iphezulu kakhulu, icinezela ngokungqongqo, kwaye ibangela umonakalo omncinci kwiikepusi.

Isicelo

Umatshini we-capping ozenzekelayo unokusetyenziswa kwiibhotile ezine-screw caps ngobukhulu obahlukeneyo, iimilo kunye nezinto eziphathekayo.

A. Ubungakanani bebhotile

Ilungele iibhotile ezinobubanzi obuyi-20-120mm kunye nobude obuyi-60-180mm. Kodwa inokwenziwa ngokwezifiso kwisayizi yebhotile efanelekileyo ngaphaya kolu luhlu ngokunjalo.

B. Ubume bebhotile

Umatshini we-capping ozenzekelayo unokusetyenziswa kwiimilo ezahlukeneyo ezifana nesikwere esijikelezileyo okanye imilo enzima.

C. Ibhotile kunye nempahla ye-cap

Nokuba yeyiphi na iplastiki yeglasi okanye intsimbi, umatshini wokuzenzela okwaziyo ukuzibamba zonke.

D. Uhlobo lwe-Screw cap

Umatshini we-capping ozenzekelayo unokujiya zonke iintlobo ze-screw cap, njengempompo, isitshizi, i-cap yokulahla njalo njalo.

E. Ishishini

Umatshini wokupakisha ozenzekelayo unokujoyina zonke iintlobo zamashishini kungakhathaliseki ukuba ngumgubo, ulwelo, umgca wokupakisha wegranule, okanye kukutya, iyeza, ikhemistri okanye nayiphi na enye imboni. Naphi na apho kukho i-screw caps, kukho umatshini we-capping ozenzekelayo oza kusebenza ngawo.

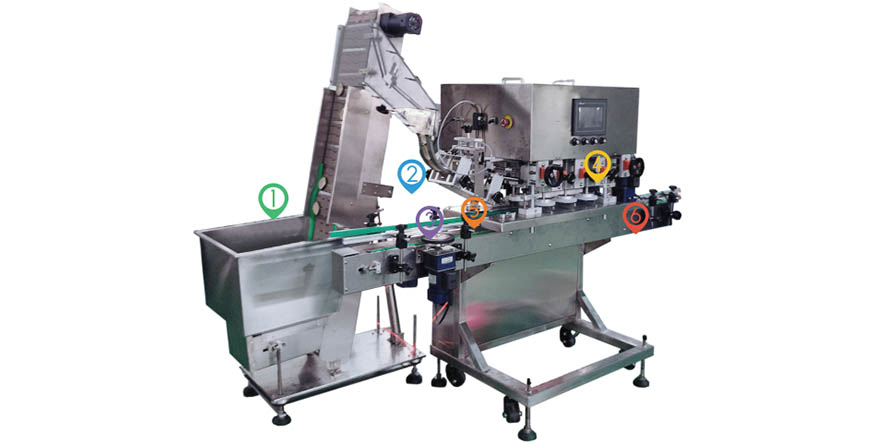

Ukwakhiwa kunye nenkqubo yokusebenza

Ibandakanya umatshini we-capping kunye ne-cap feeder.

1. ICap feeder

2. Ukubeka i-cap

3. Isahluli seebhotile

4. Amavili e-Capping

5. Ibhanti yokuqinisa ibhotile

6. Ibhanti yokuhambisa ibhotile

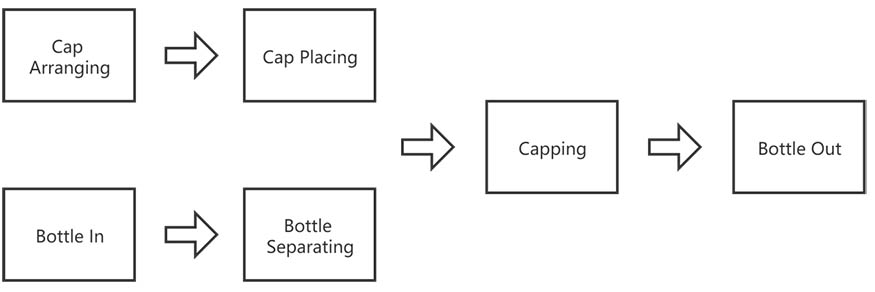

Okulandelayo yinkqubo yokusebenza

Iimbonakalo

■ Isetyenziswa kakhulu kwiibhotile kunye neekepusi zeemilo ezahlukeneyo kunye nemathiriyeli.

■ PLC&ulawulo lwesikrini sokuchukumisa, kulula ukusebenza.

■ Ukusebenza ngokulula kunye nohlengahlengiso olulula, konga uninzi lwabantu kunye neendleko zexesha.

■ Isantya esiphezulu kunye nesilungelelanisiweyo, esifanelekileyo kuzo zonke iintlobo zomgca wokupakisha.

■ Ukusebenza okuzinzileyo kunye nokuchaneka okuphezulu.

■ iqhosha elinye lokuqalisa umsebenzi lizisa lula kakhulu.

■ Uyilo oluneenkcukacha lwenza ukuba umatshini ube ngumntu kwaye ukrelekrele.

■ Umlinganiselo omhle kwimbonakalo yomatshini, uyilo olukwinqanaba eliphezulu kunye nenkangeleko.

■ Umzimba womatshini wenziwe nge-SUS 304, udibana nomgangatho we-GMP.

∎ Zonke iindawo ezidityanisiweyo ezinebhotile kunye neziciko zenziwe ngokhuseleko lwemathiriyeli ekutyeni.

■ Isikrini sokubonisa iDijithali ukubonisa ubungakanani bebhotile eyahlukileyo, eya kuba lula ukutshintsha ibhotile(Ukhetho).

■ Isivamvo se-Optronic sokususa iibhotile ezifakwe impazamo (Ukhetho).

■ Isixhobo sokuphakamisa izitephu ukuze sifakwe kwiziciko ngokuzenzekelayo.

■ Indawo ewayo isiciko inokususa iziciko zeempazamo kude (ngokuvuthela komoya kunye nokulinganisa ubunzima).

■ Ibhanti lokucofa izivalo lithambekele, ngoko liyakwazi ukulungelelanisa isiciko kwindawo efanelekileyo kwaye emva koko ucinezele.

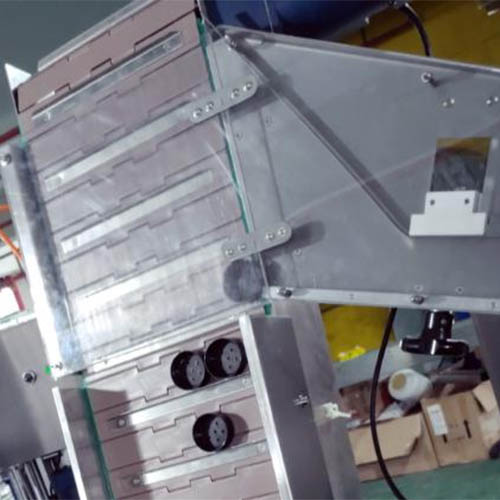

Ukrelekrele

Sebenzisa umgaqo webhalansi yeziko elahlukileyo kumacala amabini e-cap, kuphela i-cap yendlela echanekileyo enokuthi ihanjiswe phezulu. Umnqwazi kwicala elingalunganga uya kuwa phantsi ngokuzenzekelayo.

Emva kokuba umhambisi ezise iminqwazi ngaphezulu, isivutheli sivuthela iikepusi zibe yi-cap track.

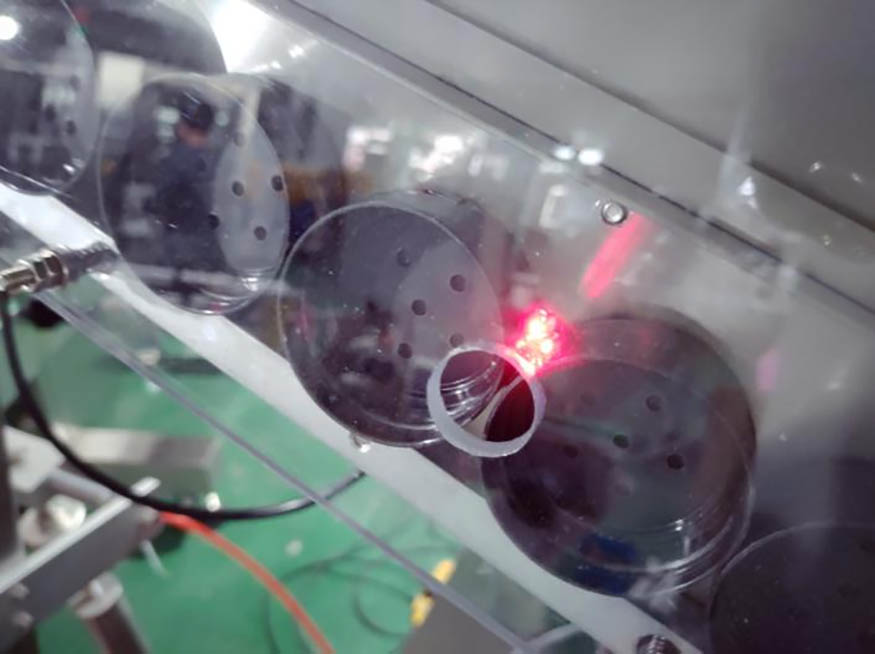

Isivamvo seziciko semposiso sinokubona iziciko eziguquliweyo ngokulula. Impazamo ye-automatic caps remover kunye nenzwa yebhotile, ukufikelela kwisiphumo esihle se-capping

Isahluli sebhotile siya kwahlula iibhotile omnye komnye ngokulungelelanisa isantya esihambayo seebhotile kwindawo yayo. Iibhotile ezingqukuva zidla ngokufuna isahluli esinye, kwaye iibhotile zesikwere zifuna izahluli ezimbini ezichaseneyo.

Ukunqongophala kwesixhobo sokubona isixhobo silawula i-cap feeder esebenzayo kwaye iyeka ngokuzenzekelayo. Kukho abenzi boluvo ababini kumacala amabini e-cap track, enye ukujonga ukuba umzila uzaliswe ngee-caps, enye ukujonga ukuba umzila awunanto.

Esebenzayo

Isantya esiphezulu sokuhambisa ibhotile kunye ne-cap feeder inokufikelela kwi-100 bpm, ezisa umatshini isantya esiphezulu ukuze ulungele umgca wokupakisha ohlukeneyo.

Izibini ezithathu zamavili zijija iikepusi ngokukhawuleza. Isibini ngasinye sinomsebenzi othile. Isibini sokuqala sinokujika umva ukwenza iikepusi zokubeka ezinzima zibe kwindawo yazo echanekileyo. Kodwa banokwenza iminqwazi ijike ukuze ifikelele kwindawo efanelekileyo ngokukhawuleza kunye namavili esibini xa ikepusi iqhelekile. Izibini zesithathu zilungelelanisa kancinane ukuze ziqinise ikepusi, ngoko ke isantya sazo siyacotha phakathi kwawo onke amavili.

Iluncedo

Ukuthelekisa kunye nohlengahlengiso lwevili lwesandla oluvela kwabanye ababoneleli, iqhosha elinye lokunyusa okanye ukuthoba isixhobo esipheleleyo se-capping kulula ngakumbi.

Izitshintshi ezine ukusuka ekhohlo ukuya ekunene zisetyenziselwa ukulungelelanisa isantya sokuhambisa ibhotile, i-bottle clamp, i-cap climbing kunye nokwahlula ibhotile. Ukucofa kunokukhokelela umqhubi ukufikelela kwisantya esifanelekileyo kudidi ngalunye lwephakheji ngokulula.

Amavili esandla ukutshintsha umgama phakathi kwebhanti ebambekayo yeebhotile ezimbini ngokulula. Kukho amavili amabini kwiziphelo ezimbini zebhanti yokubambelela. Ukucofa kukhokelela umqhubi ukuba afike kwindawo echanekileyo ngokuchanekileyo xa utshintsha ubungakanani beebhotile.

Ukutshintsha ukunyenyisa umgama phakathi kwamavili ecapping kunye neekepusi. Ukusondela komgama, i-cap iya kuba iqinile. Ukucofa kunceda umsebenzisi ukufumana owona mgama ufanelekileyo.

Ukusebenza ngokulula

I-PLC&ukulawula isikrini ngenkqubo elula yokusebenza, yenza umsebenzi ube lula kwaye usebenze ngakumbi.

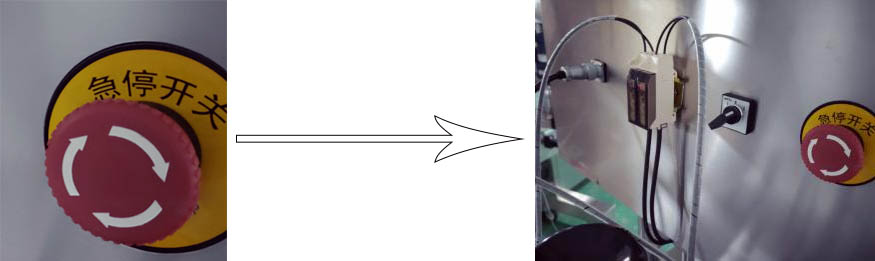

Iqhosha likaxakeka lokumisa umatshini kanye ngexesha elingxamisekileyo, eligcina umsebenzisi ekhuselekile.

| TP-TGXG-200 Umatshini wokuvala ibhotile | |||

| Umthamo | Iibhotile ze-50-120 / min | Ubungakanani | 2100*900*1800mm |

| Iibhotile ubukhulu | Φ22-120mm (ilungiselelwe ngokwemfuneko) | Ukuphakama kweebhotile | 60-280mm (ilungiselelwe ngokwemfuneko) |

| Ubungakanani besiciko | Φ15-120mm | Ukusinda okushiyekile | 350kg |

| Ireyithi efanelekileyo | ≥99% | Amandla | 1300W |

| Material | Intsimbi engatyiwa 304 | I-Voltage | 220V/50-60Hz(okanye ngokwezifiso) |

| Hayi. | Igama | Imvelaphi | Uphawu |

| 1 | Invertor | eTaiwan | Delta |

| 2 | Isikrini esibanjwayo | eTshayina | TouchWin |

| 3 | Isivamvo se-Optronic | eKorea | IiAutonics |

| 4 | ICPU | US | ATMEL |

| 5 | Ujongano lweChip | US | MEX |

| 6 | Ukucofa ibhanti | eShanghai |

|

| 7 | Series Motor | eTaiwan | TALIKE/GPG |

| 8 | Isakhelo se-SS 304 | eShanghai | I-BaoSteel |

Umatshini wokubethelwa ngokuzenzekelayo unokusebenza kunye nomatshini wokuzalisa kunye nomatshini wokulebula ukwenza umgca wokupakisha.

A. Ibhotile i-unscrambler+auger filler+automatic capping machine+foil yokutywina umatshini.

B. Ibhotile i-unscrambler+auger filler+automatic capping machine+foil yokutywina+umatshini wokuleyibhela

IZIBONELELO kwiBhokisi

■ Incwadi yemiyalelo

■ Idayagram yombane kunye nedayagram yokuqhagamshela

■ Isikhokelo sokusebenza ngokhuseleko

■ Iseti yamalungu okunxiba

■ Izixhobo zogcino

■ Uluhlu lolungelelwaniso (imvelaphi, imodeli, iinkcukacha, ixabiso)

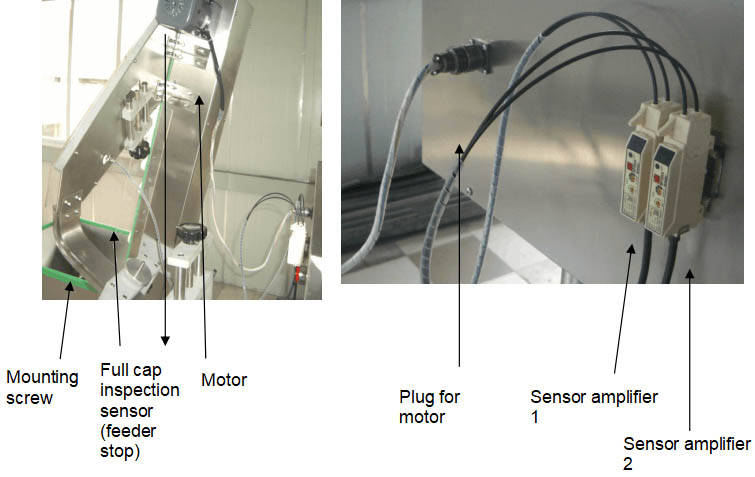

1. Ukufakwa kwe-Cap Elevator kunye nenkqubo yokubeka i-cap.

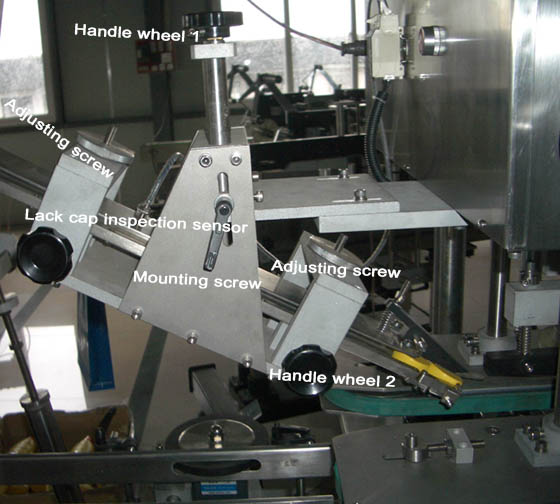

(1) Ukufakwa kwe-cap yokucwangcisa kunye nokufumanisa inzwa.

I-cap elevator kunye nenkqubo yokubeka ihlukaniswe ngaphambi kokuthunyelwa, nceda ufake i-cap yokucwangcisa kunye nokubeka inkqubo kumatshini we-capping ngaphambi kokuba usebenzise umatshini. Nceda uqhagamshele inkqubo njengoko kubonisiwe kwimifanekiso elandelayo:

Ukunqongophala kwesivamvo sokuhlola (umatshini wokumisa)

a. Qhagamshela i-cap yokubeka ithrekhi kunye ne-ramp ngesikrufu sokunyuswa.

b. Qhagamshela ucingo lwemoto kunye neplagi kwicala lasekunene kwiqela lolawulo.

c. Qhagamshela i-cap yokuhlola i-sensor epheleleyo kunye ne-sensor amplifier 1.

d. Qhagamshela i-sensor yokuhlola i-cap kunye ne-sensor amplifier 2.

Lungisa i-engile yekhonkco lokukhwela i-cap: I-engile yekhonkco lokunyuka kwekhonkco ilungelelaniswe ngokwesampulu yesampulu enikezelwe nguwe phambi kokuthunyelwa. Ukuba kuyimfuneko ukuguqula imilinganiselo ye-cap (tshintsha nje ubungakanani, ungatshintshwanga uhlobo lwe-cap), nceda uhlengahlengise i-engile yekhonkco lokunyuka kwekhonkco nge-angle yokulungisa i-screw de ikhonkco lidlulise kuphela ii-caps ezixhomekeke kwikhonkco ngecala eliphezulu. Isalathiso silandelayo:

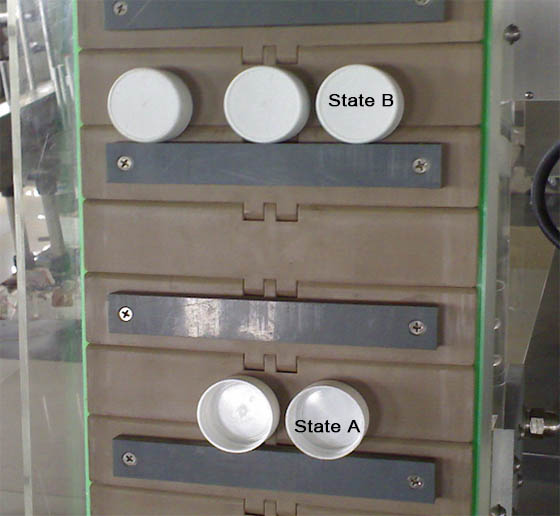

Ikepusi ekwisimo A licala elichanekileyo xa ikhonkco lokukhwela ikepusi linyusa umnqwazi.

Umnqwazi kwi-B uya kuwela kwitanki ngokuzenzekelayo ukuba ikhonkco ikwi-engile efanelekileyo.

(2) Lungisa inkqubo yokulahla umnqwazi (ichute)

I-engile yokulahla i-chute kunye nesithuba sele simiselwe ngokwesampulu enikeziweyo. Ngokuqhelekileyo ukuba akukho nkcazelo entsha yebhotile okanye ikepusi, isetingi akufuneki ihlengahlengiswe. Kwaye ukuba kukho ukucaciswa okungaphezulu kwe-1 inkcazo yebhotile okanye i-cap, umxhasi kufuneka adwelise into kwikhontrakthi okanye i-attachment yayo ukuqinisekisa ukushiya i-manufactory isithuba esaneleyo sokulungiswa okungaphezulu. Indlela yokulungelelanisa ngolu hlobo lulandelayo:

Lungisa ubude benkqubo yokulahla icap: Nceda ukhulule isikrufu sokunyusela phambi kokuba ujike ivili lomqheba 1.

I-screw yokulungelelanisa inokulungelelanisa ukuphakama kwendawo ye-chute.

Ivili lomqheba 2 (kumacala amabini) linokulungelelanisa ububanzi besithuba se-chute.

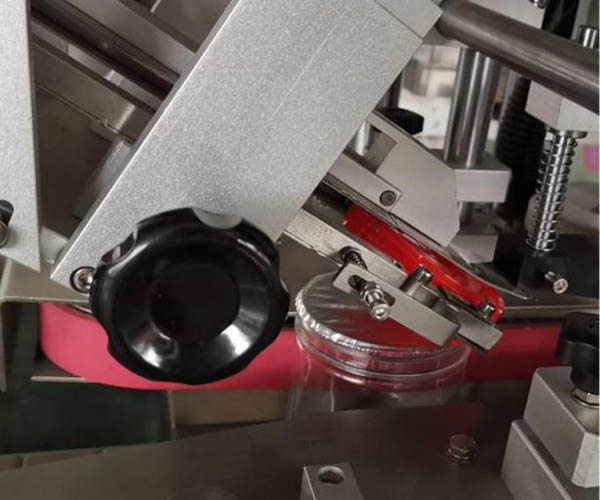

(3) Ukulungelelanisa i-cap yokucinezela inxalenye

I-cap iya kugubungela umlomo webhotile ukusuka kwi-chute ngokuzenzekelayo xa ibhotile isondla kwindawo ye-cap pressing part. Inxalenye yokucinezela i-cap nayo ingalungiswa ngenxa yokuphakama kweebhotile kunye neentloko. Kuya kuchaphazela ukusebenza kwe-capping ukuba uxinzelelo kwi-cap alufanelekanga. Ukuba indawo yecap press iphezulu kakhulu, ukusebenza ngokucinezela kuya kuchaphazeleka. Kwaye ukuba isikhundla siphantsi kakhulu, i-cap okanye ibhotile iya konakala. Ngokwesiqhelo umphakamo we-cap yokucinezela inxalenye ilungisiwe ngaphambi kokuthunyelwa. Ukuba umsebenzisi ufuna ukulungelelanisa ubude, indlela yohlengahlengiso ilandelayo:

Nceda ukhulule isikrufu sokunyusela phambi kokuba ulungelelanise ubude bendawo yokucofa i-cap.

Kukho enye indawo yokucinezela i-cap kunye nomatshini ukuze ilingane neyona bhotile incinci, indlela yokutshintsha iboniswe kwividiyo.

(4). Ukulungelelanisa uxinzelelo lomoya ukuvuthela i-cap kwi-chute.

2. Ukulungelelanisa ubude beendawo eziphambili ngokubanzi.

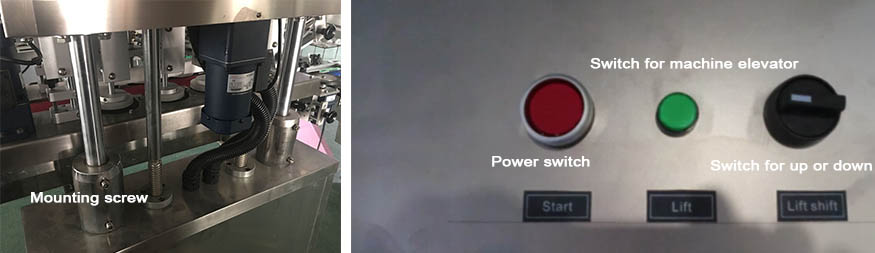

Ukuphakama kweendawo eziphambili ezifana nesakhiwo sokulungiswa kwebhotile, ivili le-gum-elastic spin, indawo yokucinezela i-cap inokulungelelaniswa iyonke yi-elevator yomatshini. Iqhosha lokulawula le-elevator yomatshini likwicala lasekunene lephaneli yokulawula. Umsebenzisi kufuneka akhulule isikrufu sokuxhoma kwiintsika ezimbini zenkxaso phambi kokuba uqalise isikhephe somatshini.

u-ø uthetha phantsi kwaye u-ø uthetha phezulu. Ukuqinisekisa ukuma kwamavili ajikelezayo kuhambelana neminqwazi. Nceda uvale amandla e-elevator kwaye ubophe isikrufu sokunyuswa emva kohlengahlengiso.

Phawula: Nceda ucinezele iswitshi yokuphakamisa (eluhlaza) ngalo lonke ixesha de ufumane indawo elungileyo. Isantya sesinyusi sicotha kakhulu, nceda ulinde ngomonde.

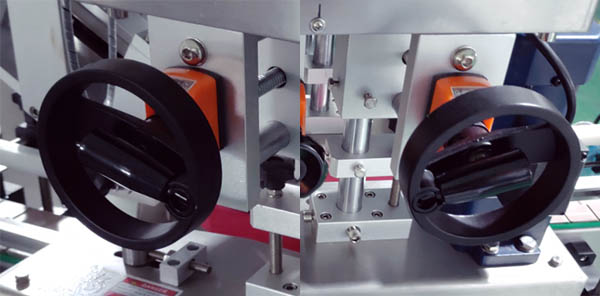

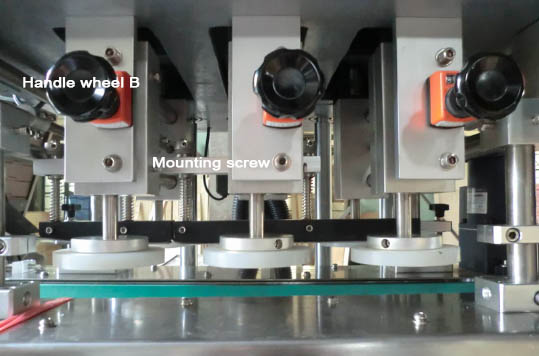

3. Lungisa ivili legum-elastic spin (izibini ezintathu zevili elijikelezayo)

Ukuphakama kwevili lokujikeleza kuhlengahlengiswa yi-elevator yomatshini.

Ububanzi ipere ivili spin ilungelelaniswe ngokobubanzi cap.

Ngokuqhelekileyo umgama phakathi kweperi yevili yi-2-3mm ngaphantsi kwe-diameter ye-cap. Umsebenzisi unokunyenyisa ububanzi bevili elijikelezayo ngevili lomqheba B. (ivili lomqheba ngalinye linokulungelelanisa ivili elijikelezayo).

Nceda ukhulule isikrufu sokunyusela phambi kohlengahlengiso lwevili lomqheba B.

4. Ukulungelelanisa isakhiwo sokulungiswa kwebhotile.

Isikhundla sokulungiswa kwebhotile sinokuhlengahlengiswa ngokulungelelanisa indawo yesakhiwo sokulungisa kunye nekhonkco ye-axis. Ukuba indawo yokulungisa iphantsi kakhulu kwibhotile, ibhotile ilula ukuyibeka phantsi ngexesha lokutya okanye i-capping. Ngokuchasene noko, ukuba indawo yokulungisa iphezulu kakhulu kwibhotile, iya kuphazamisa ukusebenza kakuhle kwamavili ajikelezayo. Qinisekisa ukuba i-centerline ye-conveyor kunye nezakhiwo zokulungisa iibhotile zisemgceni ofanayo emva kokulungiswa.

Ukuguqula umqheba wevili A (ukuguqula isiphatho ngezandla ezi-2 kunye) ukulungisa umgama phakathi kwebhanti yokulungisa ibhotile. Ngoko ke isakhiwo sinokuyilungisa kakuhle ibhotile ngexesha lokucinezela inkqubo.

Ukuphakama kwebhanti yokulungisa ibhotile ngokuqhelekileyo kuhlengahlengiswa yi-elevator yomatshini.

(Isilumkiso: Umsebenzisi unokuhlengahlengisa ubude bebhanti yokulungisa ibhotile kwi-micro-scope emva kokukhulula isikrufu sokuxhoma kwi-shaft yekhonkco e-4.)

Ukuba umqhubi ufuna ibhanti yokususa kuluhlu olukhulu, nceda uhlengahlengise indawo yebhanti emva kokukhulula isikrufu sesi-1 kunye nesijija esi-2 kunye, kwaye ukuba umqhubi ufuna ukulungelelanisa ubude bebhanti kuluhlu oluncinci, nceda ukhulule isikrufu esi-1 kuphela, kwaye ujike iqhosha lohlengahlengiso.

5. Ukulungelelanisa indawo yebhotile yokulungisa ivili kunye nentsimbi.

Umsebenzisi kufuneka atshintshe indawo yebhotile yokulungisa ivili kunye nentsimbi xa ubuyisela ingcaciso yebhotile. Isithuba phakathi kwevili lokulungisa isithuba kunye nentsimbi kufuneka ibe yi-2-3mm ngaphantsi kobubanzi bebhotile. Nceda uqiniseke ukuba i-centerline ye-conveyor kunye nezakhiwo zokulungisa iibhotile zisemgceni ofanayo emva kohlengahlengiso.

Ukukhulula isikrufu sokulungelelanisa kunokulungelelanisa indawo yebhotile yokulungisa ivili.

Umqheba wokulungelelanisa okhululekileyo unokulungelelanisa ububanzi bokuhlambalaza kumacala omabini okuhambisa.